The MyoRobot

The MyoRobot automated Biomechatronics System

Our engineered MyoRobot represents an automated biomechatronics system for robust, objective and versatile assessment of muscle or polymer materials (bio-)mechanics. It covers multiple levels of muscle biosensor assessment, e.g. calcium sensitivity of the contractile apparatus, speed of shortening or passive visco-elasticity. It therefore, replaces previously tedious manual protocols performed on single muscle fibers, small fiber bundles or whole muscles, to now yield exhaustive information on active/passive biomechanical properties across multiple organ scales in an automated robotized fashion. Until now, only very few commercial biomechatronics systems that meet resolution, experimental versatility and optical analysis are available, limiting the research potential for myobiology. Our MyoRobot combines optical force transducer technology with high precision 3D actuation (e.g. voice-coil actuation), and a customized control software, enabling modular experimentation packages and automated data analysis.

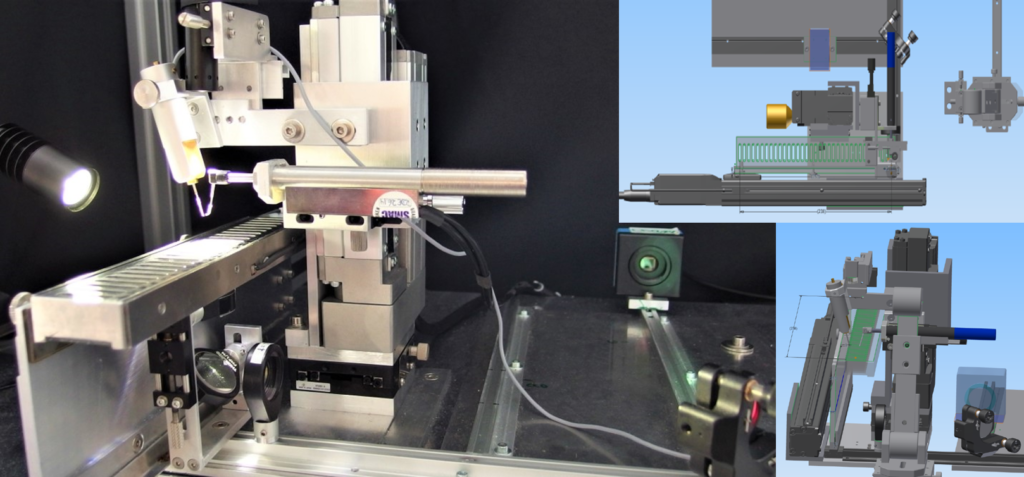

Photograph of the current MyoRobot automated biomechatronics systemwith in-built optics for morphological sample assessment (left) as well as 3D design aspects of the system (right).

Two axes, driven by linear steping motors featuring position feedback, allow fast solution exchanges by lifting the sample and moving the multi-well rack that holds up to 32 incubation wells to a new position. These wells have been designed to fit various sample sizes, reaching from whole muscles down to single fibers and a multitude of linear (bio-)materials (e.g. spider silk, biopolymers). Once the sample is mounted between the pins of Force Transducer (FT) and Voice Coil (VC), the system provides active muscle force recordings, while also allowing to impose stretches or slacks upon the sample to address its passive properties by ultrafast (slack-test) or ‚quasi-static‘ VC pin displacement (stress-strain relationships). The VC operates based on magnetic Lorentz-force induced within current-driven coils (like in a loudspeaker) and can be move in either very slow and constant or almost instantaneous fashion. Just recently, fiber cross section measurements were implemented by engineering a custom-made optical system below the rack, which magnifies the sample on a camera approximately 24x and allows to displays sarcomere patterns. This significant improvement now enables us to upgrade the system to include sarcomere length measurements as readout or control variable and therefore, eliminates the need for external microscopes as is a constraint to most commercial muscle biomechanics systems on the market.

References:

- Haug M, Reischl B, Prölß G, Pollmann C, et al. (2018) The MyoRobot: A novel automated biomechatronics system to assess voltage/Ca2+ biosensors and active/passive biomechanics in muscle and biomaterials. Biosens Bioelectron. 102:589-599. doi: 10.1016/j.bios.2017.12.003.

- Haug M, Meyer C, Reischl B, Prölß G, et al. (2019) MyoRobot 2.0: An advanced biomechatronics platform for automated, environmentally controlled skeletal muscle single fiber biomechanics assessment employing inbuilt real-time optical imaging. Biosens Bioelectron. 138:111284. doi: 10.1016/j.bios.2019.04.052.